מייבש לחות FD-D320K מבית LUKO.

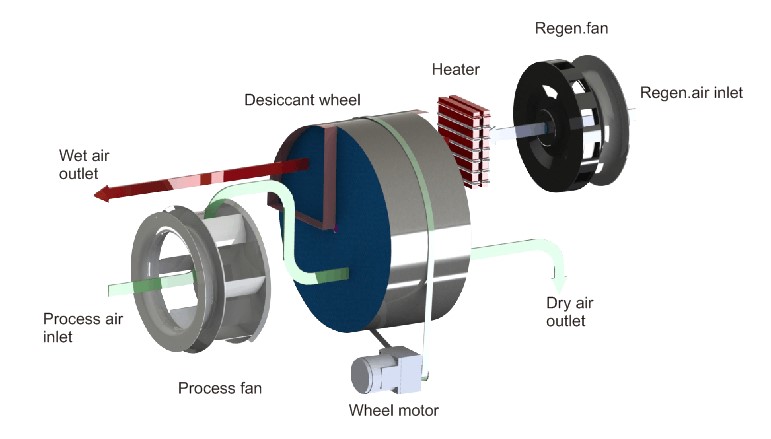

This series is normally with low regeneration temperature.It is suitable for environment with surplus of heat. And it is usually apply in application that require to achieve low dew point.

KEY FEATURES

- High Performance Desiccant Rotor with high moisture adsorption rate for reliable performance and continuous trouble-free operation. Lifespan of the Rotor wheel is 5 – 8 years under normal operating condition (non-corrosive environment and regeneration temperature of below 140°C)

- Come with advance touch control panel with built-in Honeywell Temperature and Humidity Sensor for real-time monitoring, which is easy to operate and user friendly.

- Our desiccant dehumidifier is built-in with dual-speed adjustable centrifugal fan which can be set to run in High and Low speed for the Process Air Fan. It is also come with separate fan for Regeneration Air.

- Simple and elegant design with unique frame for better sealing and insulation structure to reduce heat loss.

- Body material build with SPCC metal and Power-Coated paint for better resistant over corrosion.

- Built with reliable electrical component from well-known reliable brand. e.g. ABB, OMRON, Schneider and others.

- Low operation cost and energy efficient. Our desiccant dehumidifier used PTC and SCR build heating technology with advance processor-controlled regeneration heat, which can save 20% -30% of power consumption.

- Structure built for convenient installation and easy maintenance with replaceable F5 filter and washable rotor. It is also build according Fire Prevention Standard, to ensure safe operation of the machine.

- Inlet and Outlet air of the machine is conformance to duct connection standard of ISO7807 to simplify air duct connection.

- Equipment is conformance to TUV, GS, ROHS and CE Standards.

מפרט טכני

| Capacity(@20°C,60%RH) | 1.2kg/h |

| Process Air Flow | 320m³/h (100PA) |

| Reactivation Air Flow | 120m³/h (50PA) |

| Process air in & out | ⌀125mm |

| Regen. air in & out | ⌀80mm |

| Rated Power | 1.9KW |

| Rated Current | 8.3A |

| Primary Filter | G4 efficiency |

| Heater Type | PTC |

| Controller Type | digital controller |

| Voltage /Frequency | 220V/50Hz/1P |

| Applied Temperature | -20°C~60°C |

| Body Material | Metal Steel with Powder Coated (optional: SUS304 – additional cost) |

| Weight | 45KG |

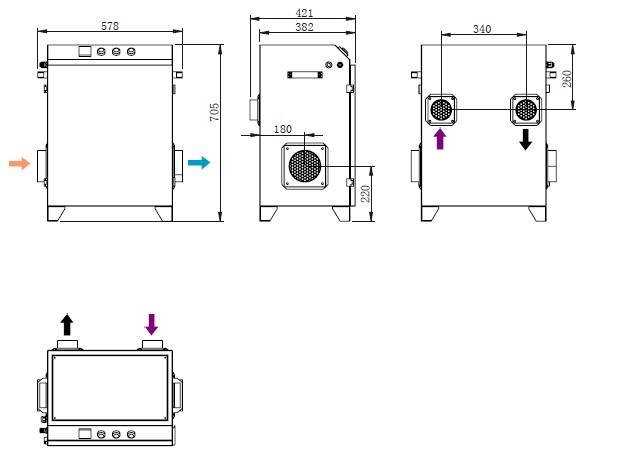

| Dimension | 578*421*705mm |

*Technical Specifications and dimensions are subject to change without prior notice

BILL OF MATERIALS

| Items | Parts and Components Brand | Manufacturer |

| Machine Main Body | SPCC | LUKO |

| Rotor Belt | GOODUSE | GOODUSE |

| Desiccant Wheel | LUKO’s Custom Made Desiccant Wheel | LUKO |

| Process Air Filter | G7 primary filter / Or Custom Made | LUKO |

| Regeneration Air Filter | G7 primary filter / Or Custom Made | LUKO |

| Alarm Indicator Device | Schneider | Schneider |

| Indicator Light | Schneider | Schneider |

| Power-On Button | Schneider | Schneider |

| Power-Off Button | Schneider | Schneider |

| Manual / Auto Switch | Schneider | Schneider |

| Delay Timer | OMRON | OMRON |

| Master Switch | ABB | ABB |

| Motor Protection Device | Schneider | Schneider |

| Air Switch | Schneider | Schneider |

| Intermediate Relay | OMRON | OMRON |

| AC Contactor | Schneider | Schneider |

| Process Air Fan | German Rosenberg | German Rosenberg |

| Regeneration Air Fan | Fanshida | Fanshida |

| Heater | LUKO’s Custom made | LUKO |

| Duct Flange | Galvanized Type | GANGYANG HVAC |

WORKING PRINCIPLE

DIMENSION